Rotary Bobbins Sewing machine accessories, Sewing machine, Sewing machine repair

round bobbin, shown in Figure 4-8, will provide the most compact design. It can be seen, in Figure 4-8, that the round bobbin provides a uniform tension, all 360 degrees around the bobbin, for both layer and random windings. The other benefit, in using a round bobbin, is the reduction and minimizing of the leakage inductance caused from the bowing.

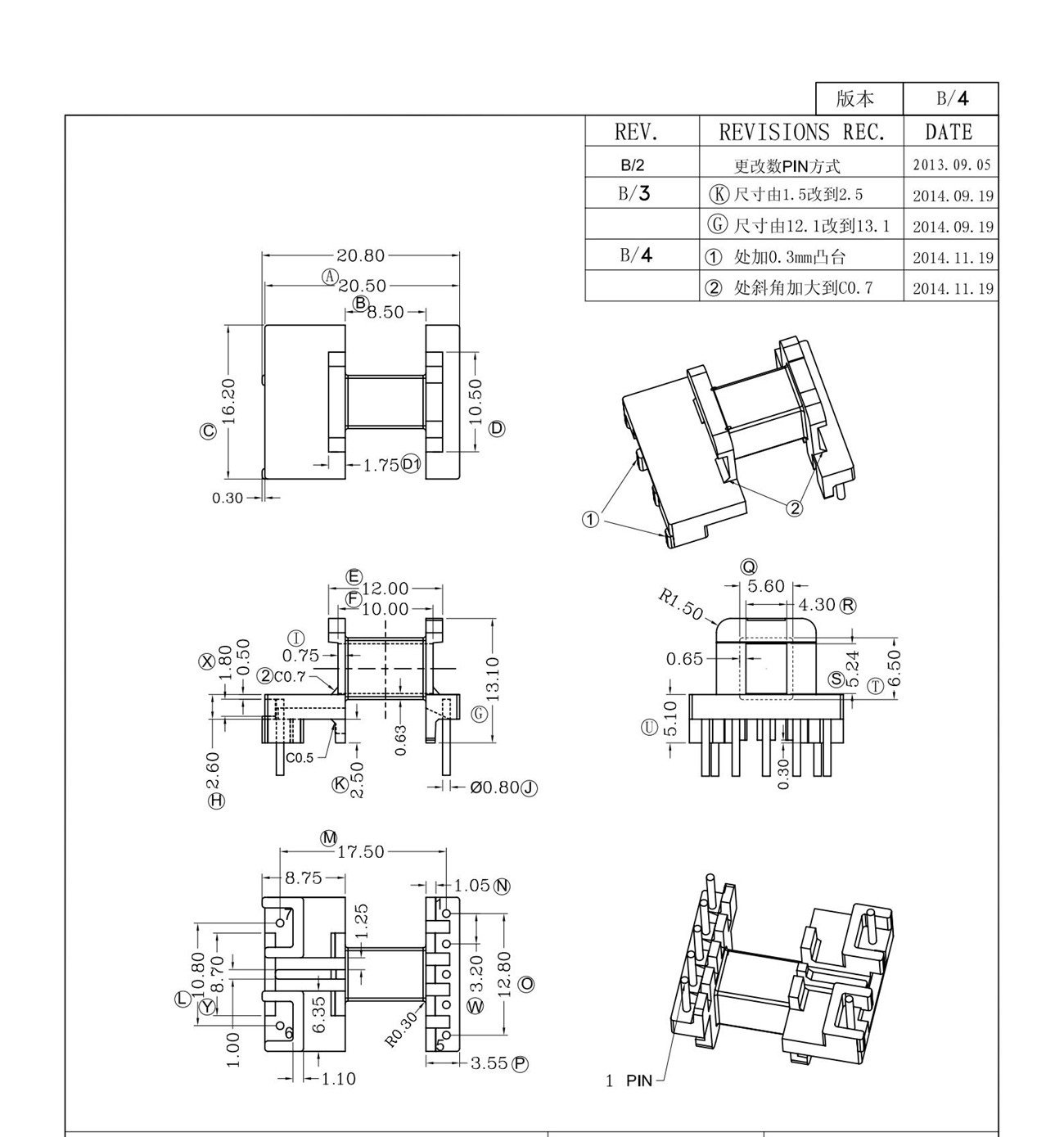

EE20 Transformer Bobbin Horizontal (6+6P) FM2065

Transformer and Inductor Design for Optimum Circuit Performance. Texas Instruments 1 SLUP205. Bobbin Winding Area, AW': 1.23 cm2 Winding Area Width/Height: 2.15 / 0.62 cm

» Split Bobbin Transformer

With core parameters calculated and confirmed we now need to calculate the appropriate wire sizes. First requirement is to calculate the available bobbin width (BW A) from the actual bobbin width (BW), the number of layers for the primary winding (L) and the margin width (M). The primary winding can be 1, 2 or 3 layers, but

Aftermarket Worryfree 14mm 3 Layer Bobbin Coil Former Bobbin for Transformers Coils Pot Core

Linear Transformers Communications/RF Switch Mode Power Current Transformer Unlikely Yes Possible Possible Unlikely Yes Possible Possible Unlikely Yes Unlikely Possible Unlikely. Bobbin Type and Size "A" "B" RM Bobbins EFD Bobbins PQ Bobbins EP Bobbins. B-EIM41X25V-12-1-PBT BC-EIM41X25V-12-1-PBT B-EIM41X30H-10-2-GFN3 B-EIM42X14.8H-10.

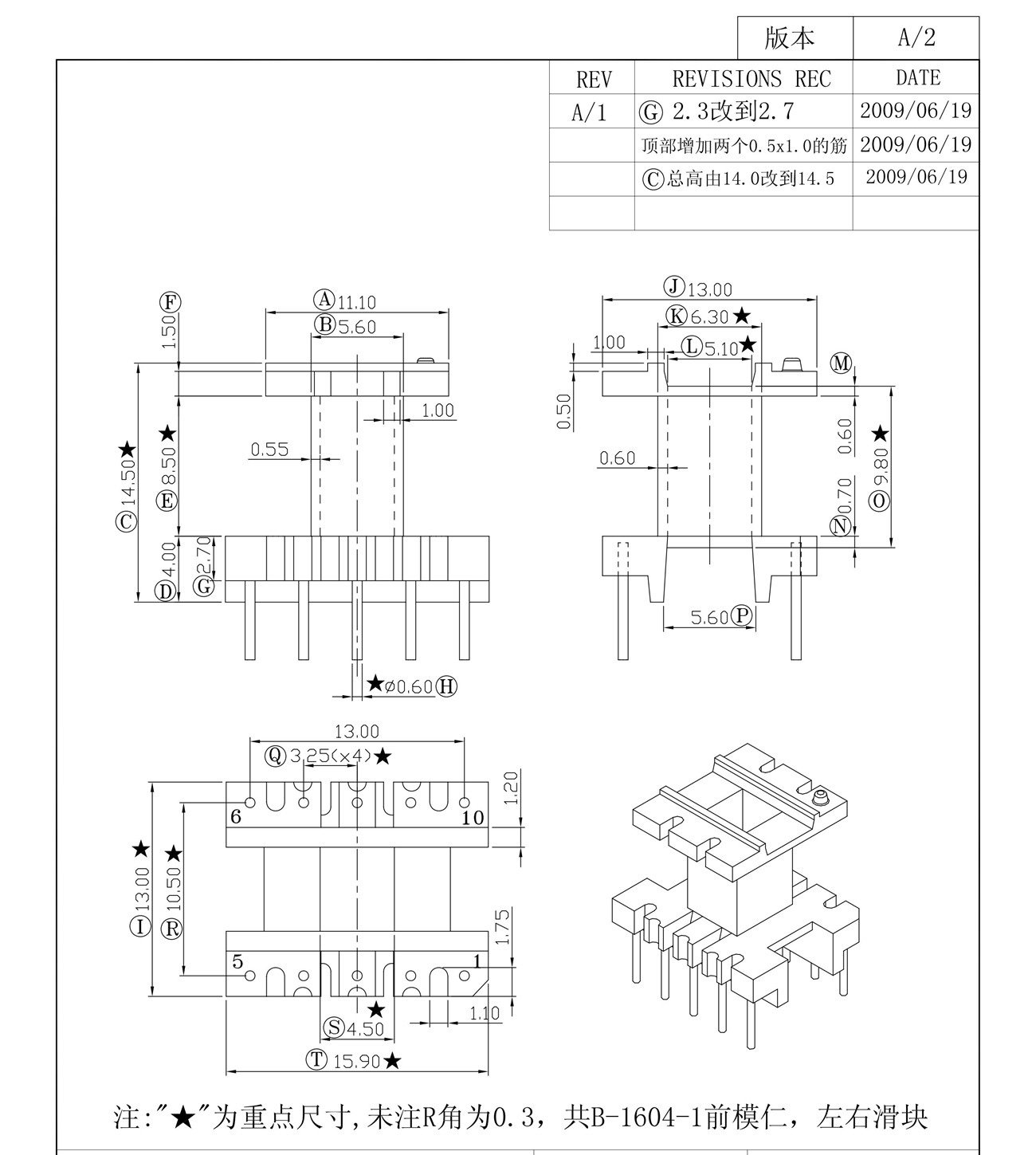

EE16 Horizontal Transformer Bobbin (5+2P) F1675

right to left. On the final layer, spread the winding evenly across entire bobbin. Finish this winding on pin(s) 2. Add 1 layer of tape, item [3], for insulation. Bias Winding Start on pin(s) 6 and wind 16 turns (x 2 filar) of item [6]. Winding direction is clockwise. Spread the winding evenly across entire bobbin. Finish this winding on pin(s) 5.

Pin on Amplifier

bobbins to cover the "in between" lamination range (EI150 to EI300) that help address the needs of the larger transformer industry. The finished article- 15kVA bobbin wound assembled transformer using a 3" x 6" bobbin with UL94V0 flammability, Class N 200°C Lamination Centre Limb Size USA/ UK reference Stack Heights

Quickreference guite to winding transformers. NO 3 correction is made for losses.

For transformers with power ratings less than 1 kVA, manufacturing trends tend to favor bobbin-wound coils. A bobbin-wound coil consists of layers of wire precision-wound on a rigid form. The rigid form, or bobbin, is the support platform and electrical isolation for the windings. Bobbin forms are commonly molded from thermoset materials such as

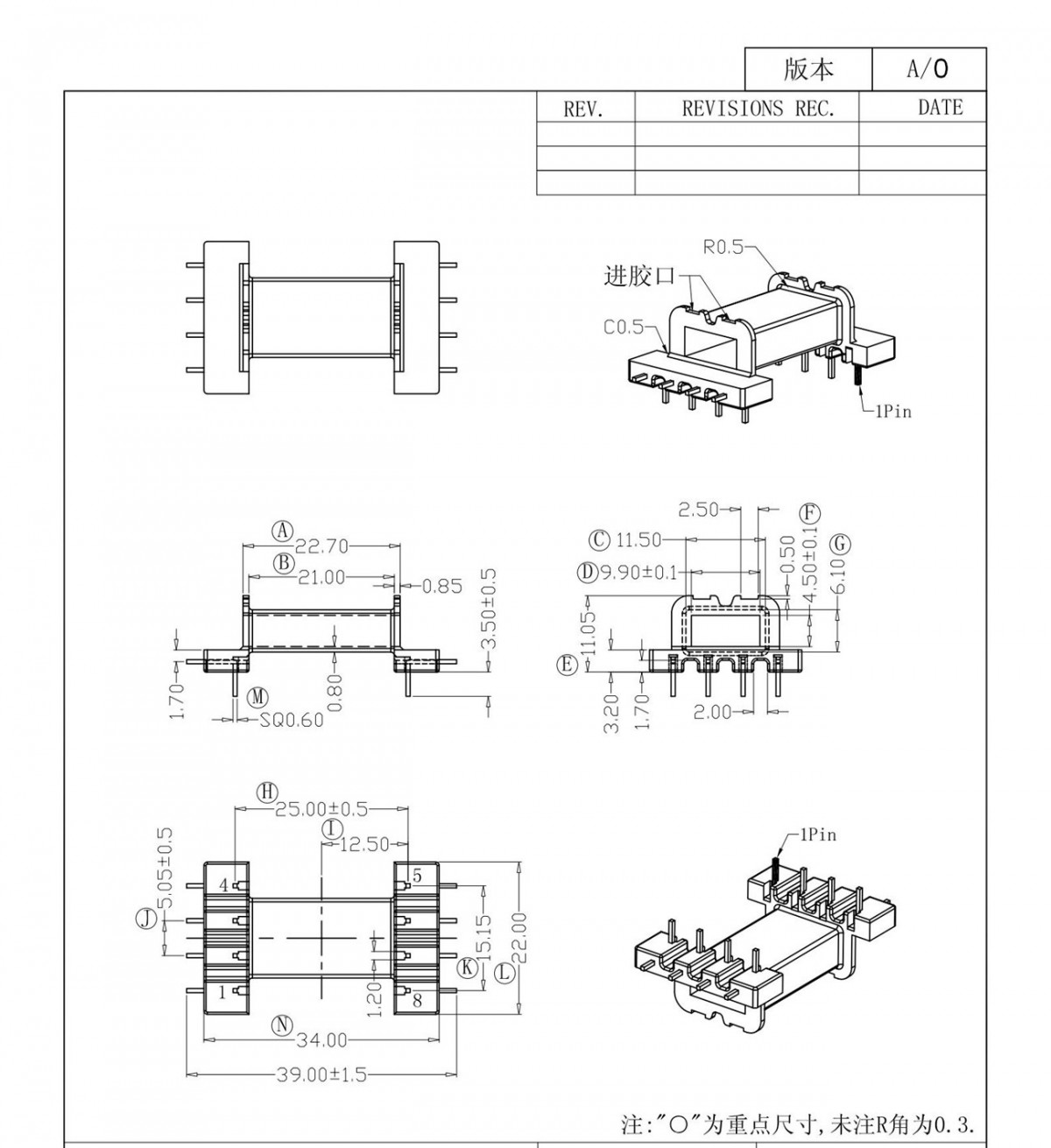

EFD22 Horizontal Transformer Bobbin(4+4P) F2228

Bobbin manufacturer's catalogs are used to provide mechanical dimensions for transformer design. The bobbin manufacturers in Appendix A offer a wide variety of bobbin styles for standard ferrite core sizes in materials suitable for high volume production. Many ferrite core manufacturers also carry bobbins for their standard core sizes. PI-1907.

Mentor Unschuldig Marmelade transformer bobbin sizes chart Lamm Verwalten Vorsicht

ETD29. In this section, we have listed core and bobbin geometries that are most commonly used to build switching transformers. Do reach out to us if you need a specific size that isn't listed here. You may use the data provided to finalize the transformer design and request a quote and samples. Footprint data provided is subject to change so.

EE16 Horizontal Transformer Bobbin(5+2P) F16123

Spread the winding evenly across entire bobbin. Wind in same rotational direction as primary winding. Finish this winding on pin(s) 11. Add 3 layers of tape, item [4], for insulation. Primary Winding (Section 2) Start on pin(s) 2 and wind 38 turns (x 1 filar) of item [6] in 2 layer(s) from left to right. At the end of 1st layer, continue to.

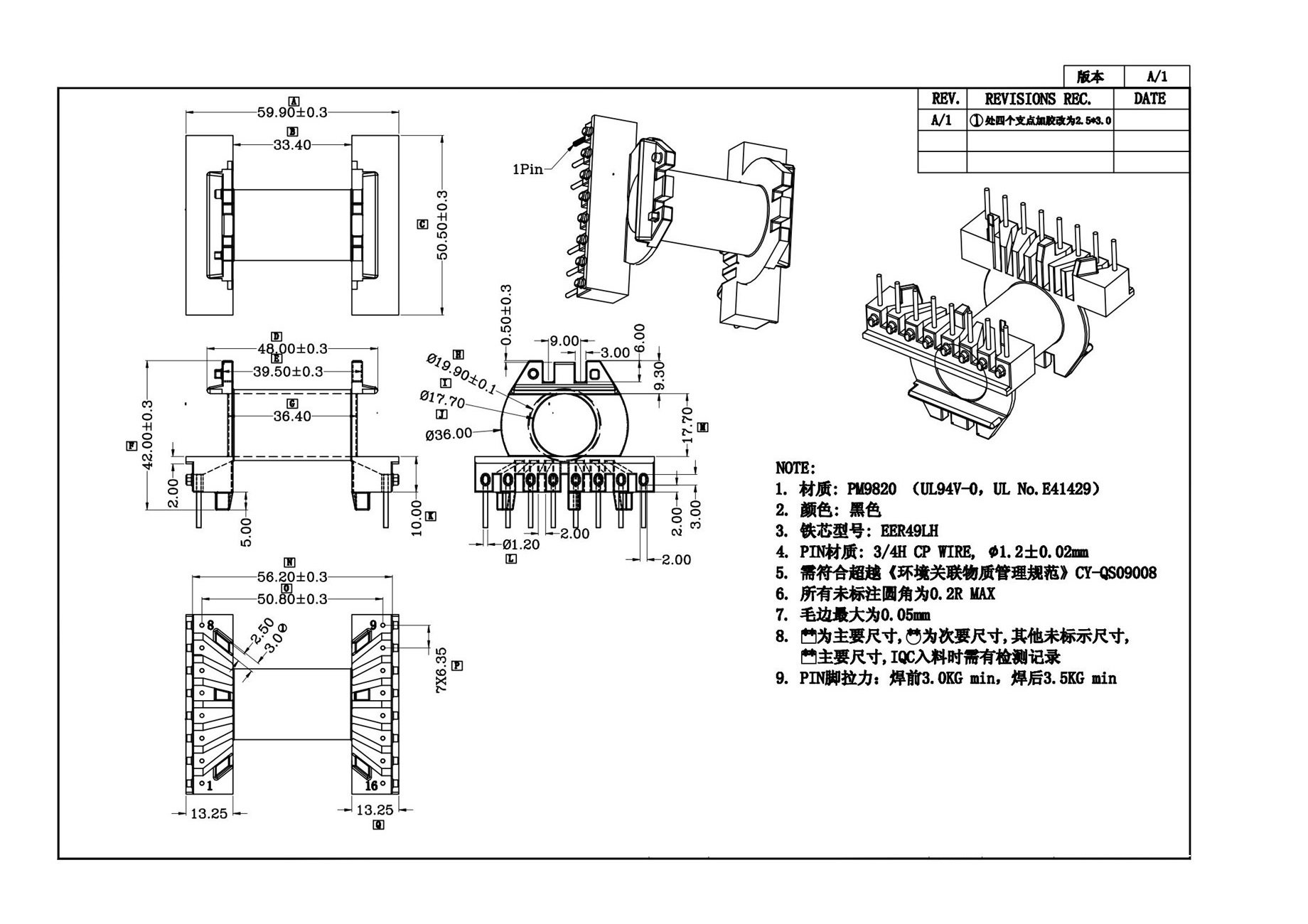

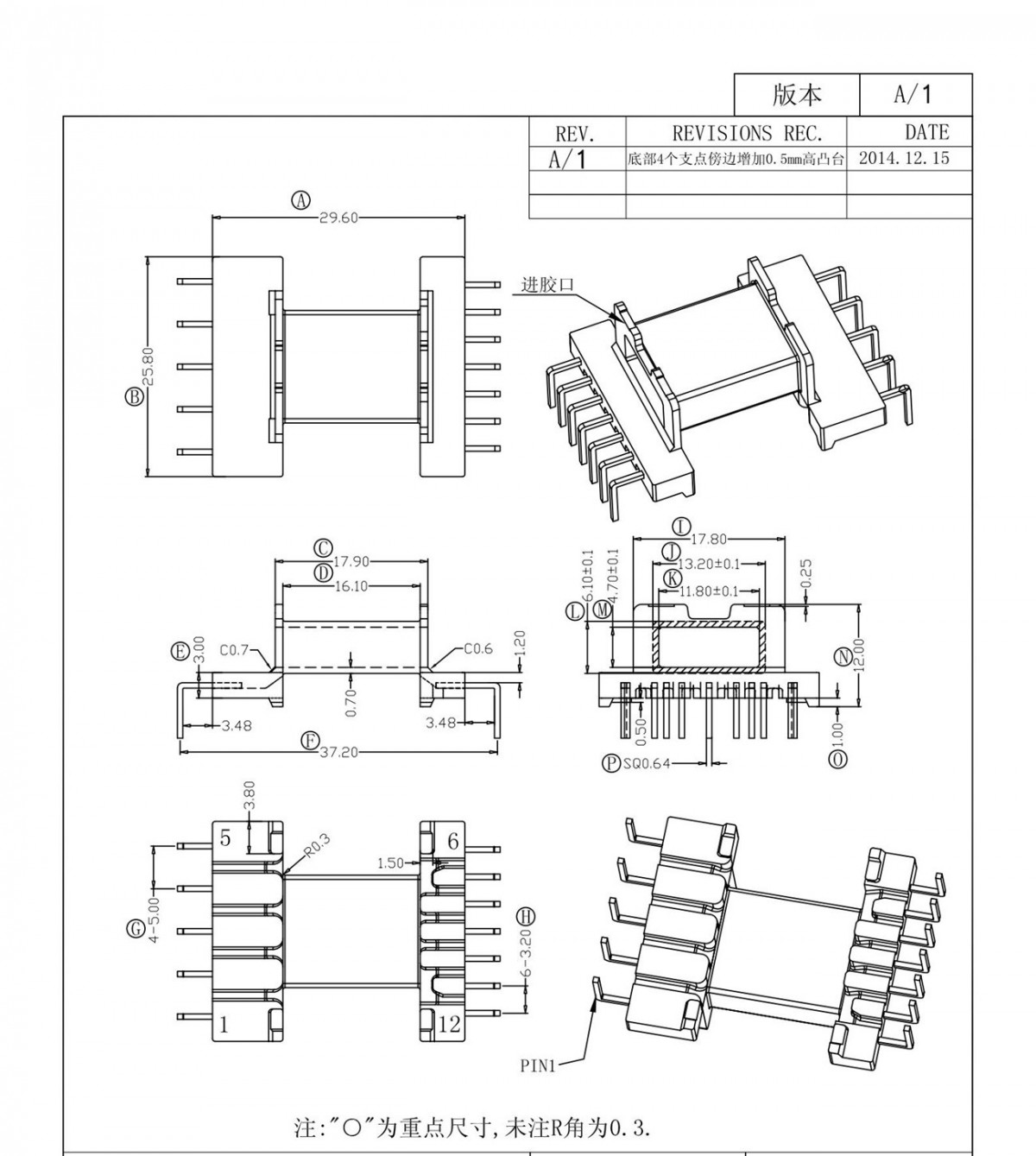

EER49 Horizontal Transformer Bobbin(8+8Pin) F4909

STOCK # DESCRIPTION SIZE BOB1 Bobbin 2996 13/ 16" x 7/ 16" BOB2 Bobbin (55623) 13/ 16" x 11/ 32" BOB3 Bobbin (40264) 13/ 16" x 11/ 32" BOB4 Bobbin For Juki DDL555 13/ 16" x 11/ 32" BOB7 Bobbin (18034) Consew 206RB 1" x 13/ 32" BOB8 Home Bobbin (2518) Singer 15CL, 15 13/. THD123WH Redi Wound Bobbins DD L White 13/

EE20 Horizontal Transformer Bobbin (2+2P) F2028

Primary Current = Sum of o/p Volt and o/p Amp divided by Primary Volts x efficiency. The efficiency of small transformers can deviate between 0.8 to 0.§6. A value of 0.87 works extremely well for regular transformers. The appropriate wire size needs to be determined for the winding.

Windings calculator for a amplifier viprock

Transformer/Inductor Bobbin Sizes. I have to design a 150 Ampere, 1.5 mH Inductor for a power supply project assigned to me, and off-the-shelf components are to be used. My instructor is insistent on using a transformer Bobbin to wind the conductor around, however wants me to optimize the design to standard bobbins available commercially.

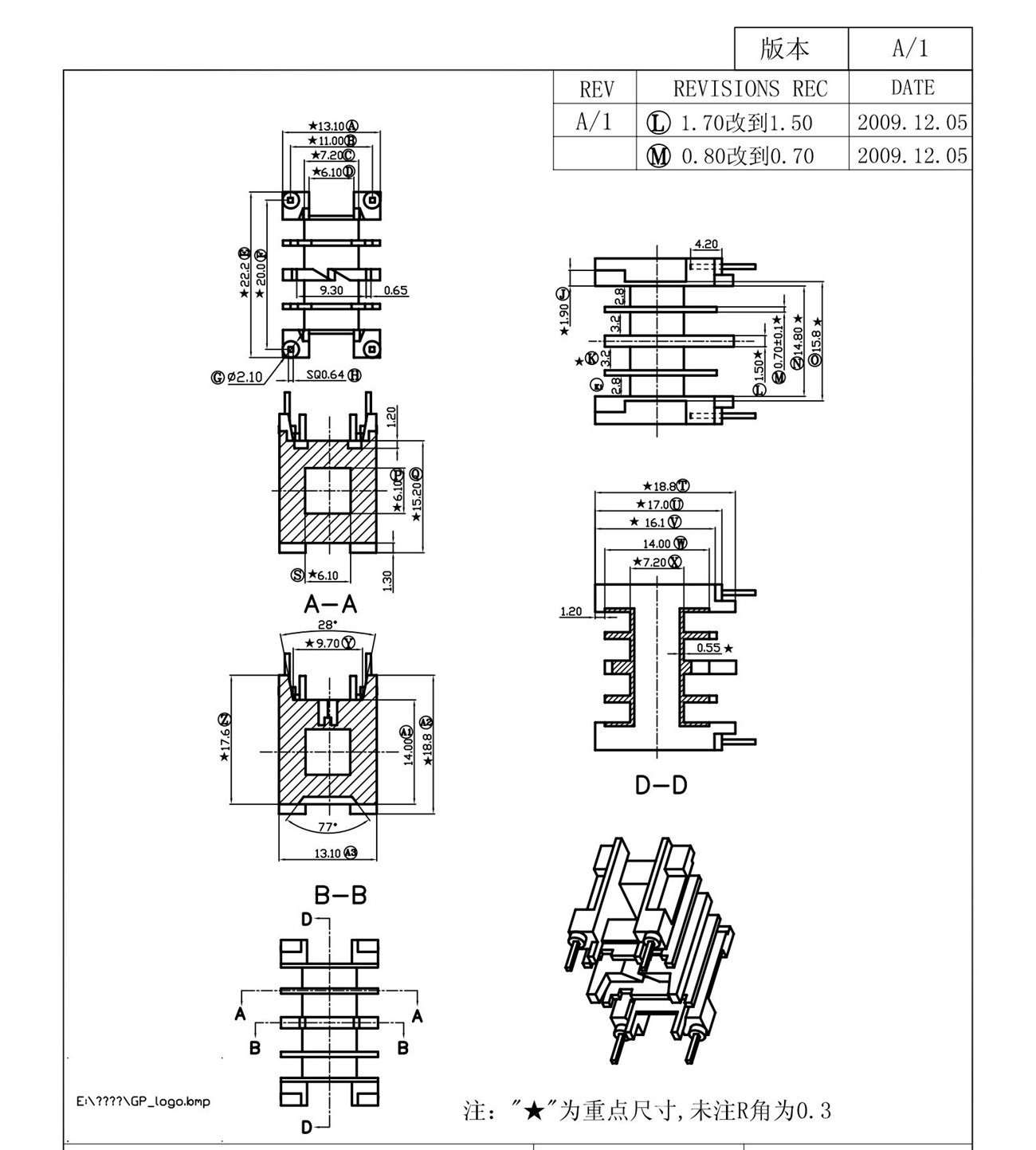

EE16 Transformer Bobbin Vertical (5+5P) F1604

Approximate length of copper wire = number of turns x perimeter of bobbins. Cross-sectional area of copper. Volume = approximate length x cross-sectional area. Mass = copper density x copper volume . Primary Side calculation of Copper Weight. Perimeter of the bobbin = 1.75 x 4 = 7 inch = 0.1778 m. Therefore, the length of the turn is 0.1778

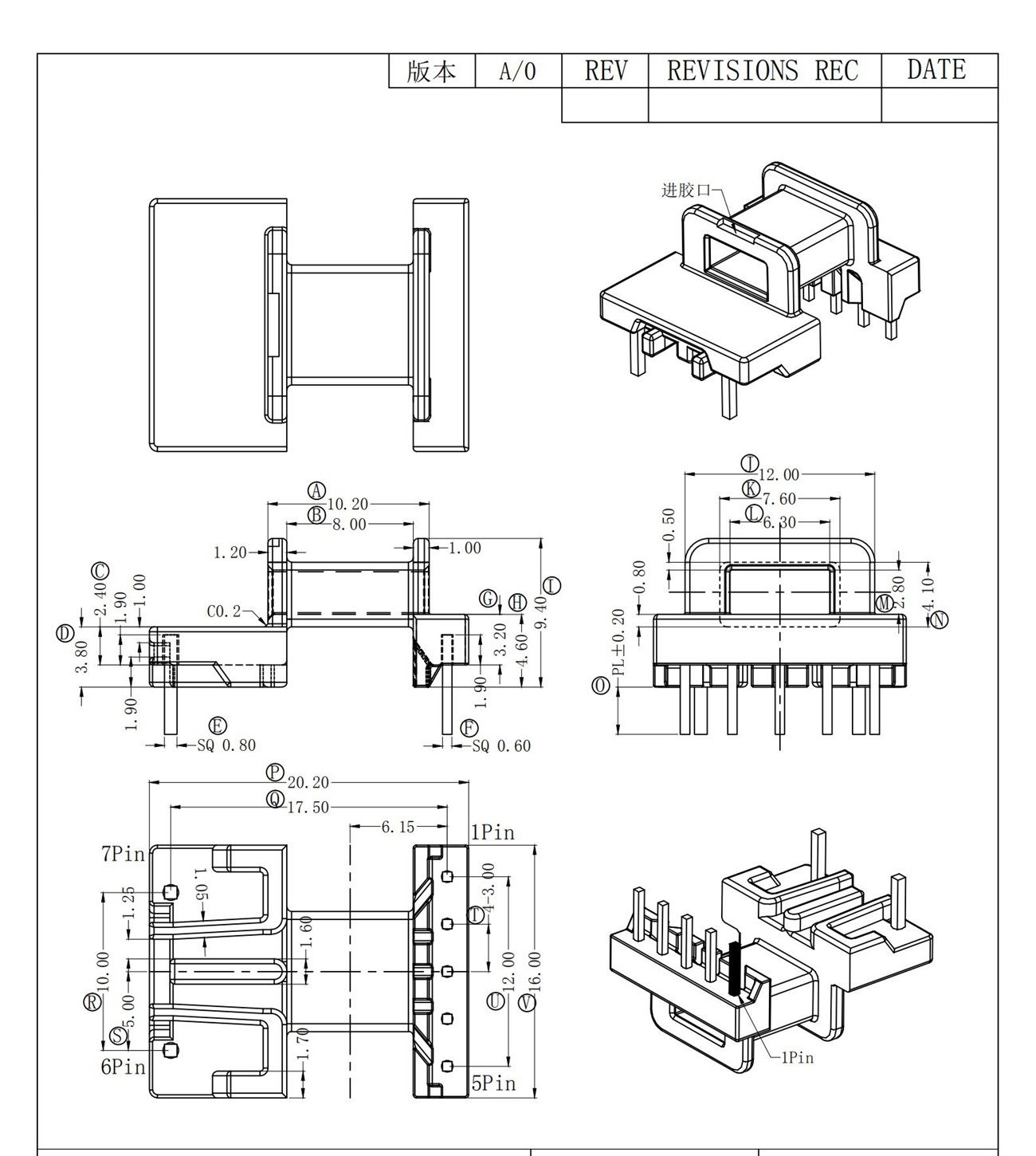

EFD25 Transformer Bobbin Horizontal (5+7Pin) F25102

High Profi le Vertical PC Transformer Bobbins . . . . . 44 Low Profi le Horizontal PC Transformer Bobbins. . . . 47. control styles available in various shaft sizes. In addition, we produce a complete line of stud and ball knobs. These items are described in our Knob Catalog. Please

Transformer Plastic Bobbin at Rs 5/piece Transformer Bobbins in Pune ID 19811914948

P. S. Leakage inductance is a measure of how much magnetic flux couples from the primary into the secondary. The greater the distance between the primary and the secondary, the fewer flux lines there will be to couple the two windings together. Fewer flux lines coupling the windings means larger values of leakage inductance.